Hang Time

Caliper's Quinner Baird on developing the HIDDEN Hangers.

One of the latest HIDDEN home goods products co-engineered with Madrid-based design studio Caliper is an upcoming set of hangers. In a previous HIDDEN.RSRCH article some light was shed on the long-running partnership and how many of the HIDDEN accessories and home goods go from concept to production.

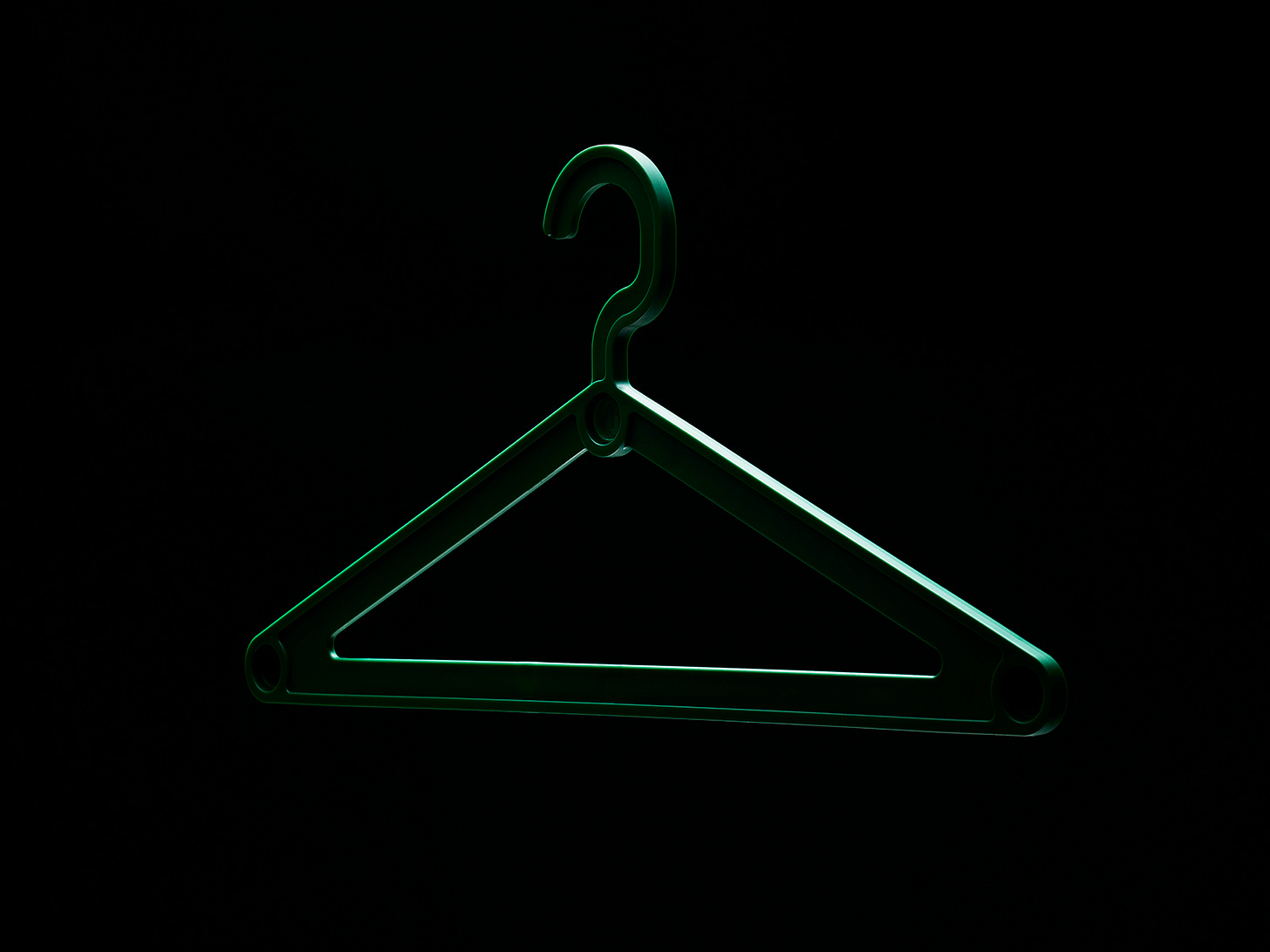

Caliper’s Quinner Baird began the development process around a year ago. The idea was to make an object that balanced the relative affordability of readymade wooden and plastic hangers but complemented the physical-meets-digital aesthetic that characterizes much of the HIDDEN apparel and previous home goods.

Initial concepts explored the idea of using aluminum as the medium, giving individual hangers a premium look and feel but it was discovered that not only was the production process extremely wasteful, the costs would have been significantly higher to the end customer, negating the notion of making a product relatively accessible on a regular basis.

After further experimentation, polypropylene plastic delivered the best balance of quality, cost, and aesthetic. It’s a thermoplastic with multiple uses, but among them is it’s what Eames has replaced its fiberglass material for its iconic shell chairs. Plus, it’s a material that can be recycled easily.

Another way to make the end product more cost-effective (and as it turns out, energy-efficient) without sacrificing quality was utilizing an injection molding process. This involves injecting molten plastic into molds (usually metal) to create various parts. One product that uses this to great effect is the Gundam plastic model kit, which in a meta move, recently made a model kit of one of the injection molding machines at Bandai’s factories.

Usually the cost-prohibitive part of this goes into the tooling and making the custom mold, but since these hangers are meant to be a recurring part of the HIDDEN brand, the initial investment was worth it.

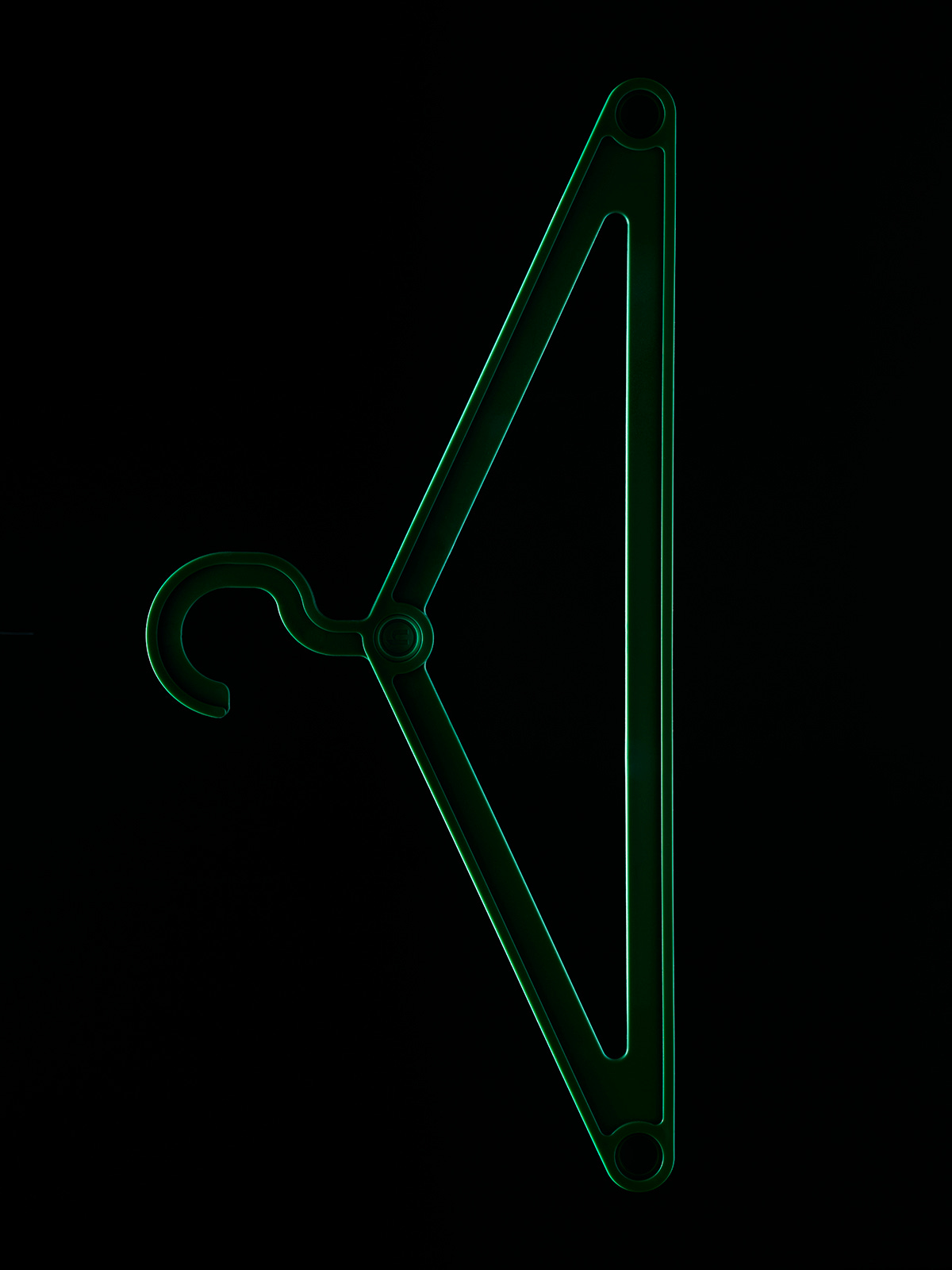

Subconsciously taking notes from the way in which plastic model kits can be separated from their sprues and snapped together, there is an ingenious method for the hangers to be joined together in a neat stack for shipping or storage. Three round pins were designed in a triangular shape, which slide into other hangers without being too tight.

Meanwhile, the functional T-section of the hanger utilizes a larger cross section to better help garments keep their shape, while providing improved structural rigidity. It also references a common architectural feature used in construction—another subtle nod to the various inspirations.

Believe it or not, the hook was the part of the design that required the most deliberation. Various forms were tested before landing on the final shape, an ideal compromise between a design that could support heavier garments while retaining it shape, while being able to snugly hang on a closet in a relatively flush manner.